Automobile Mould

-

High quality plastic injection molding automobile mold

1. Start from part design analysis.

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3. If product is complex, moldflow report will be present as well.

4. Indoor workshop ensures you high quality under good control.

5. Normally it takes 15-60 days to make mold, precise time depends on complexity of design.

-

Toy Car Plastic Injection Mould for Kids Toys

Our kids electric car mould is highly flexible and customizable. We can create toy cars of any brand, size, shape, or design to precisely fulfill your needs. Our expert team collaborates with you to ensure a hassle-free and seamless manufacturing process. By employing the latest technology and techniques, our mould consistently generates high-quality and precise outcomes.

-

OEM Experienced Injection Plastic Auto Car Bumper Mould/Mold

Advanced internal parting surface technology is usually adopted in the design of Auto bumper mould. The advantage is that the parting line is hidden on the non-appearance surface of the bumper, and the parting line cannot be seen after being assembled on the car, which will not affect the appearance of the product. However, the difficulty and structure of this technology are more complicated than that of the outer parting type bumper, and the technical risk is also higher. The cost and price of the Auto bumper mould will also be much higher than that of the outer parting type bumper. It is widely used in high-end cars.

-

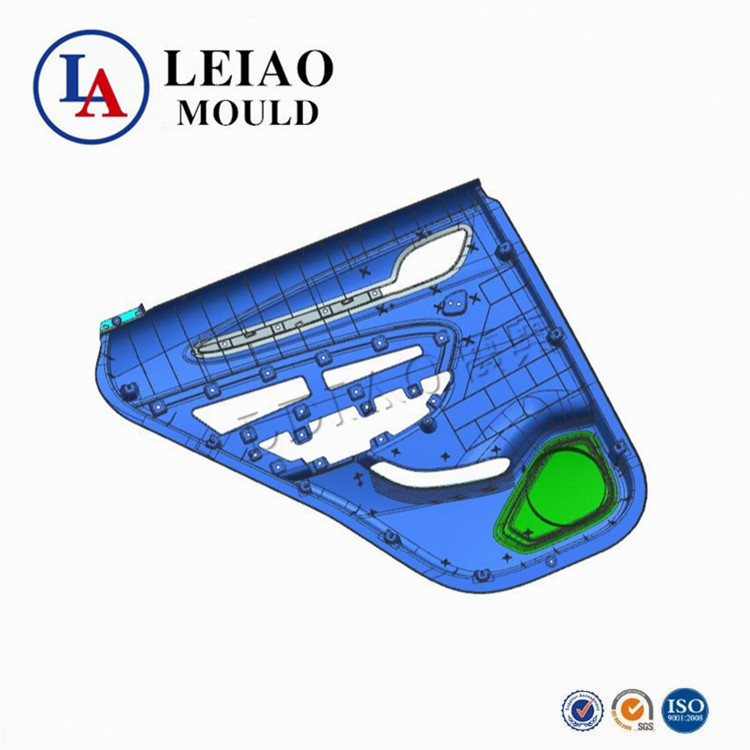

Auto Door Panel Injection Mould

We product Car Door Panel Injection Mould with Gas Assistance Technology. Professional mold manufacturer, provide lower cost, more efficient quality solutions.

Gas Assistance technology can be applied to all kinds of plastic products, as well as automotive plastic products. Such as handle, door panel, tailgate upper trim panel, etc -

Automotive blow molding air duct mold

Auto air ducts are an essential part of any vehicle’s HVAC system, and their production requires high-quality blow molds that deliver consistent performance and durability. Our air duct blow molds are designed to meet the demanding requirements of automotive manufacturers, delivering accuracy, speed, and efficiency in the production of air ducts for cars, trucks, and other vehicles. Our blow molds are made from premium quality materials that are heat and wear-resistant, ensuring long-lasting performance even in the most demanding production environments. Our team of skilled engineers uses the latest CAD/CAM software and CNC machines to design and manufacture blow molds with exceptional accuracy and precision, ensuring a seamless fit with your existing production equipment. Our air duct blow molds are available in a wide range of sizes and shapes to meet your specific production requirements. From round and rectangular ducts to complex, multi-branch designs, we have the expertise and technology to design and produce the perfect mold for your needs. Our molds are compatible with a range of materials, including thermoplastic elastomers (TPE), polypropylene (PP), and high-density polyethylene (HDPE).

-

Auto Door Panel Mould

The car door panel mould is located on the inner side of the car door and is installed in four positions on the front, rear, left and right of the car door. It is an important part of the car interior parts. The door panel of the car is an appearance part, and no welding line is allowed. When injection moulding, it is necessary to adjust the welding line to the non-appearance area or eliminate the welding line. Leiao’s door panel mould adopts a 3-point sequential needle valve hot runner system, which is controlled by an oil cylinder or a cylinder. The opening and closing of 3 hot nozzle heads to achieve the injection moulding effect without welding lines. The selection of the glue inlet position is mainly determined by the mould flow analysis, and the type of glue mouth is mainly used for large nozzles and diving. But one thing needs to be noted: the glue feeding position is in the non-appearance position or the position that is not easy to see after the door panel is assembled, such as the glue opening at the bottom of the door panel mould.

-

Car cup holder mold

From product design, mold design to mass production, we have long been committed to automotive interior and exterior accessories, such as universal cup holders, speaker injection molds. With our rich experience and long-term work, we have a large range of car accessories, and car cup holders are a good example. The car cup holder is made of a car cup holder injection mold. The car cup holder injection mold is completely designed and manufactured by our company.

The first step is from the car model to the product design that fits the model, and with our experienced team of in-house engineers, we can perfectly complete this step and the next step of cup holder injection mold design. For automotive cup holder injection mold design, we will use techniques such as mold flow analysis to design the most economical and effective cup holder injection mold. Then, we will carry out the injection molding process of the car cup holder, and at the same time, we will also carry out the assembly of the leather case to create a qualified car cup holder. Our high-precision custom car cup holder injection mold will ensure the quality of all processes.

-

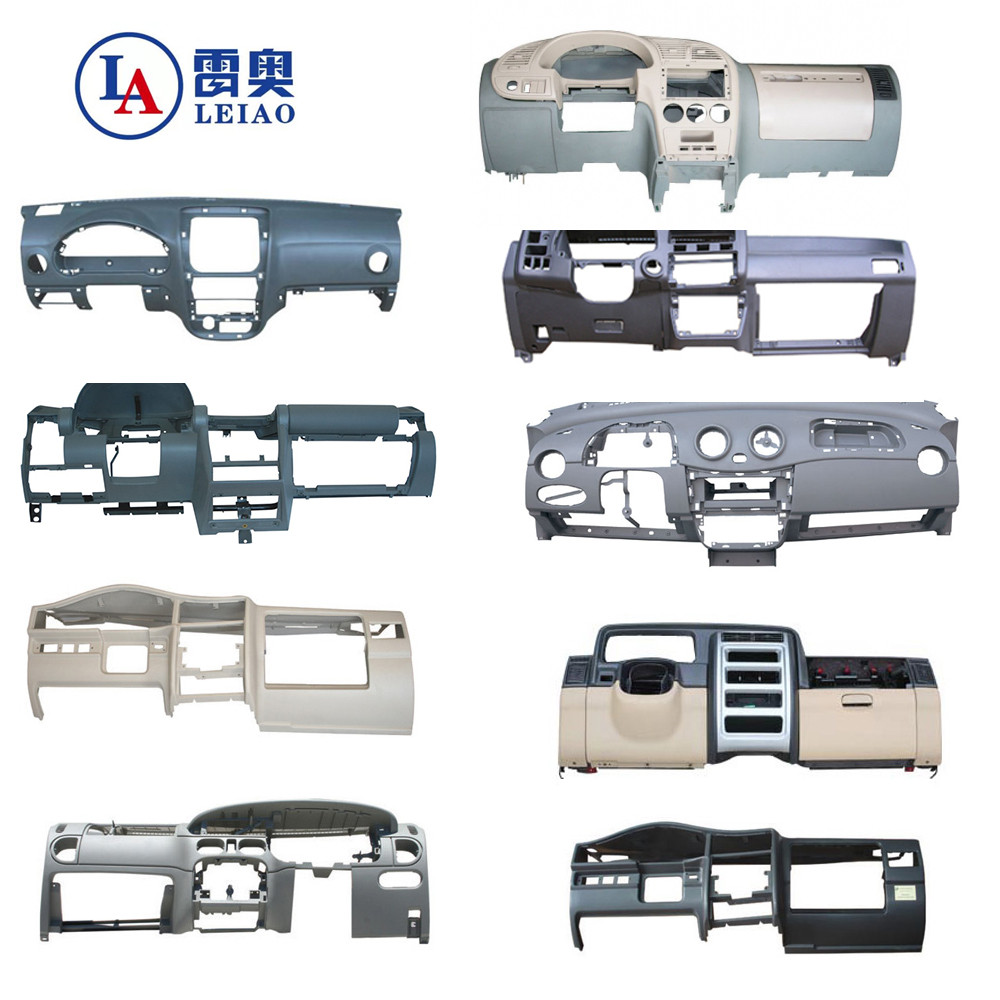

Automotive Plastic Parts Mould Automobile Interior and Exterior Trim Parts Mould

This is Automotive Plastic Parts we made, tested qualified, very beautiful, we have rich experience in Automotive Plastic Parts , specially docking the main engine factory, accessories factory, can customize high, low, medium, different requirements of Automotive Plastic Parts Mould.cantact me at any time,dear friend.

-

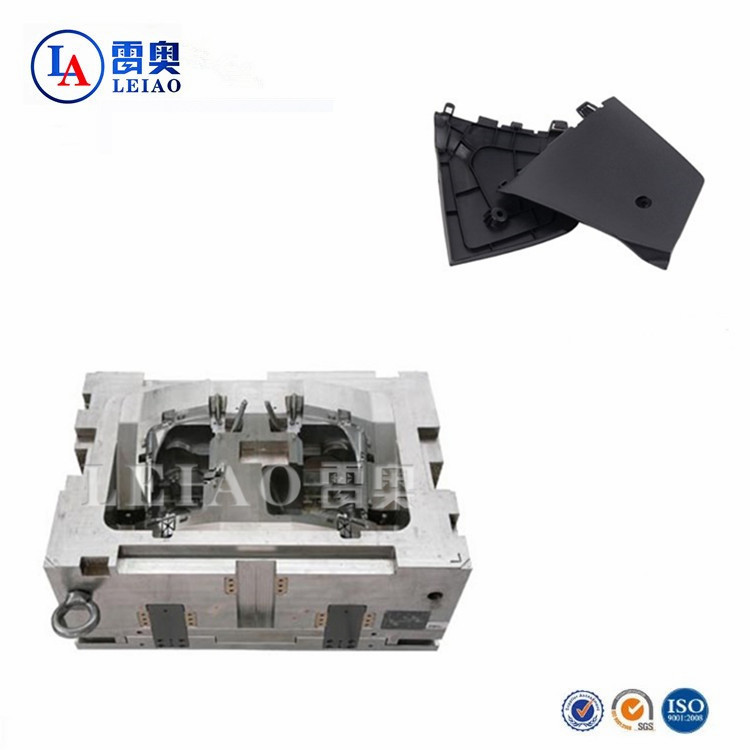

Plastic Injection Auto Door Visor Mould

Plastic Injection Auto Door Visor Mould

-

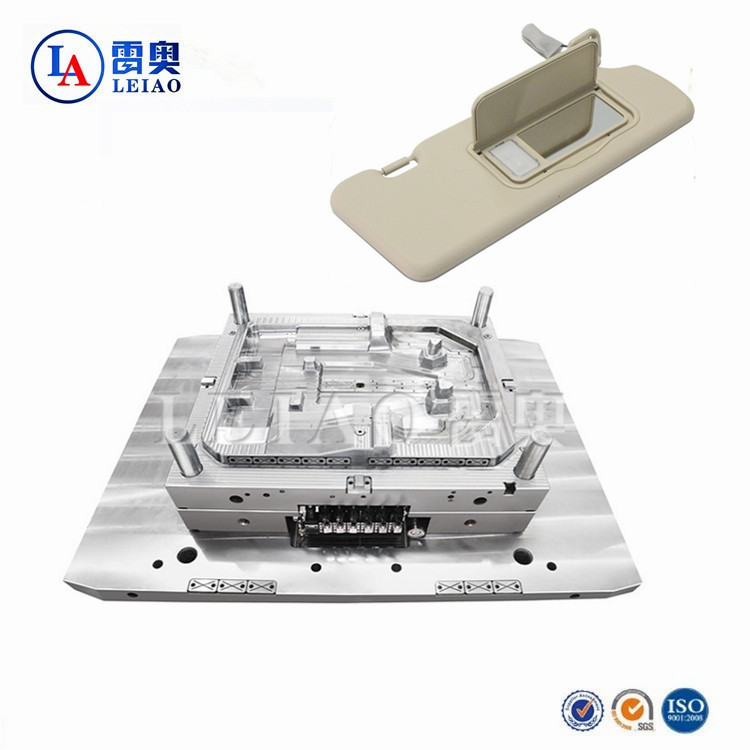

Auto Parts Car Dashboard Mould Plastic Injection Mold Moulding Molding

Professional plastic mold, plastic injection mould customization, rich experience, welcome to inquire at any time

-

Car Central Control Panel Mould Manufacture Auto Part Mold

We have been engaged in plastic mold and plastic products export services, we have been engaged in this service for 10 years, our clients come from many countries, like United States, United Kingdom, Spain, Australia, Singapore, Russia, Japan, etc.

-

Taizhou Auto Exterior Parts Wiper Mould Plastic Injection Mold Maker

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are car parts mold,household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.