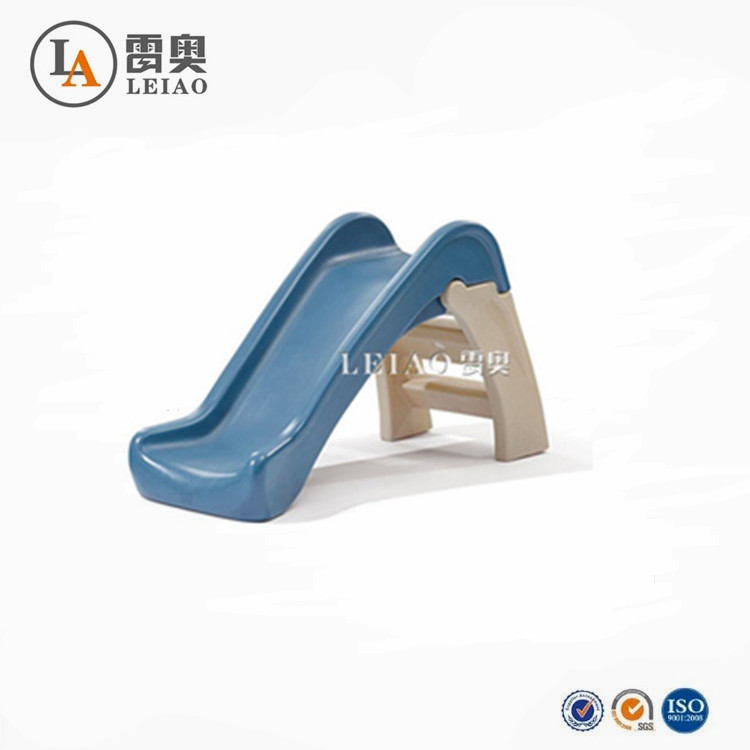

Children Plastic Outdoor Slide Injection&Blow Mould

Product Description

|

Model NO. |

LA23-1026 |

Application |

Blow molding mold |

|

Runner |

Hot Runner/Cold Runner |

Design Software |

UG |

|

Installation |

Fixed |

Certification |

TS16949, ISO |

|

Trademark |

LA |

Customized |

Customized |

|

After-sales Service |

1year |

Transport Package |

Wooden Case |

|

Specification |

|

HS Code |

8480719090 |

|

Origin |

China, Zhejiang, Taizhou |

Production Capacity |

650 Set/Year |

Mold Traits

There are several areas to note when designing and making fan leaf molds.

1

Selection of mold dividing line: it is suggested to extend the middle line of the side of the blade to facilitate mold matching and avoid batch front.

2

Inlet position: It is recommended to set one inlet to each blade to prevent uneven glue filling.

3

Setting of cooling waterway: to be in place, sufficient, to prevent excessive deformation of products.

4

Internal mold processing: this depends on your company's equipment conditions and the selected process flow.

5

Mold assembly: pay attention to the batch front and exhaust.

Why choose Leiao Mould for the production of household Mould?

Leiao Mould is a one reliable and professional high quality custom plastic mould manufacturer engaged in mould design, manufacturing & produce a variety of plastic injection moulds.

We have a mature team of highly skilled designers, Engineers, Project Managers and Fabrication Technicians that ensure strictly control all of the project success.

We Specialize in manufacturing all kinds of plastic moulds, such as plastic crate moulds, Car parts mold, plastic pallet moulds, plastic chair moulds, plastic household moulds, plastic Home-appliance moulds, Plastic industries moulds, tableware moulds, etc.