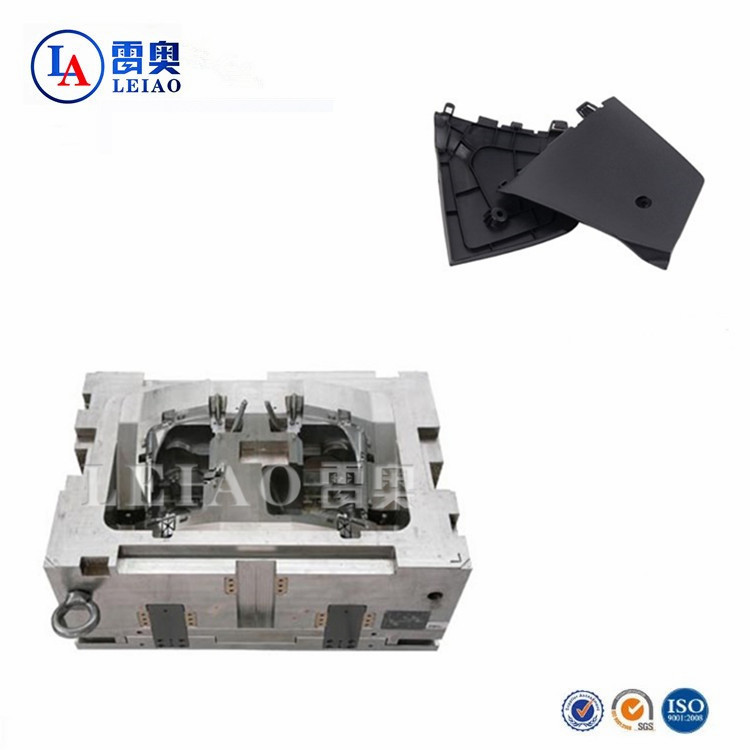

Die For auto parts

-

Automotive Plastic Parts Mould Automobile Interior and Exterior Trim Parts Mould

This is Automotive Plastic Parts we made, tested qualified, very beautiful, we have rich experience in Automotive Plastic Parts , specially docking the main engine factory, accessories factory, can customize high, low, medium, different requirements of Automotive Plastic Parts Mould.cantact me at any time,dear friend.

-

Car Central Control Panel Mould Manufacture Auto Part Mold

We have been engaged in plastic mold and plastic products export services, we have been engaged in this service for 10 years, our clients come from many countries, like United States, United Kingdom, Spain, Australia, Singapore, Russia, Japan, etc.

-

Taizhou Auto Exterior Parts Wiper Mould Plastic Injection Mold Maker

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are car parts mold,household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.

-

Car Windshield Wiper Blade Mold Plastic Auto Windscreen Wiping Blades Injection Mould

1. The speed of product ejection don’t be too slow, a little faster than normal speed to make the ejection plate in place.

2. Advising to use Robot Hand to pick products to ensure mould safety, because there are angle lifts and other complex structures.

3. Advising to use PA66+30%GF raw material to produce, which has good hardenability and toughness with a long lifetime; but PBT+30%GF raw material is soft and crisp, which is easily broken. -

Injection Car Lamp Plastic Cover Auto Lamp Mould

The automobile lamp mold includes headlight mold and taillight lens mold, etc. The previous CAE analysis is used to predict the molding pressure, reduce the actual molding pressure and reduce the adhesive front mold; for the automobile lamp headlight BEZEL, through the previous CAE analysis, the automobile lamp is very high, so the mold needs to be polished to the mirror.

-

Car Bumper Precision Hot Runner Auto Parts Plastic Injection Mould

Mould characteristics:Leiao uses an internal fractal structure for the bumper mold. Compared with the traditional external fractal structure design, the internal fractal design has higher requirements on the die structure and the die strength, inner fractal structure of the mold produced by the bumper mold design concept more advanced.

-

Plastic Moulding Manufacture Customize Safety Helmet Mould OEM Custom Parts Mold

Helmets are divided into full helmets, 3/4 helmets, half helmets, assembled helmets, etc. The main material of the helmet is ABS resin material, which is an engineering plastic with strong impact ability and good dimensional stability.

-

OEM Auto Plastic Injection S136 Mould for Car Wheel Hubcap

For the large size of the left and right rear hubcap products of the car, Injection molding is difficult to fill the full actual production difficulties, By performing the CAE optimization analysis, To determine the hot flow channel injection molding scheme, The 6 point hot flow nozzle direct pouring molding scheme of the product, And targeted combined with the production of actual equipment, The CAE analysis results of the 6-point pouring scheme are analyzed quantitatively, Avoid the uncertain manufacturing risk caused by manufacturing experience alone; Using the UG mold design function, Two family modes of one mode and two holes are designed, Innovative design of cylinder T-groove variable pumping core slider mechanism and cylinder + thimble plate complete release mechanism, Save the mold design space and the amount of mold materials used, The old design is reasonable, Stable and reliable, and It provides a useful reference for the mold design and production of similar plastic parts.

-

Plastic Injection Car Wheel Hubcap Mould

For the large size of the left and right rear hubcap products of the car, Injection molding is difficult to fill the full actual production difficulties, By performing the CAE optimization analysis, To determine the hot flow channel injection molding scheme, The 6 point hot flow nozzle direct pouring molding scheme of the product, And targeted combined with the production of actual equipment, The CAE analysis results of the 6-point pouring scheme are analyzed quantitatively, Avoid the uncertain manufacturing risk caused by manufacturing experience alone; Using the UG mold design function, Two family modes of one mode and two holes are designed, Innovative design of cylinder T-groove variable pumping core slider mechanism and cylinder + thimble plate complete release mechanism, Save the mold design space and the amount of mold materials used, The old design is reasonable, Stable and reliable, and It provides a useful reference for the mold design and production of similar plastic parts.

-

Technology Make Car Mold of Plastic Car Steering Wheel Mold

The steering wheel is a composite material made of metal as skeleton material and plastic by injection.

(1)Raw materials and the typical formula. Polypropylene modified with thermoplastic elastomer SBS can be used as special material for automobile steering wheel.

(2) Main production equipment. A screw right-angle injection machine with an injection capacity of 2000g, with a locking force of about 4000 kN. The injection capacity of 2000g can meet the needs of various automobile steering wheel production. 9 The choice of screw type is to ensure the plastic plasticizer and uniform coloring.

(3) Preparation process.The metal frame of the steering wheel is made for the metal processing process, which is omitted here. The hygroscopicity of the modified polypropylene automobile steering wheel is not high (less than 0.02%), but in order to ensure quality stability, it is still advisable to dry at 90 ~ 100 ^ for 3-4h in advance. The steering wheel is shaped by injection. Because this product has a metal skeleton, the plastic in the mold flow channel is longer, the plastic cooling speed is faster, so the injection speed should be slightly faster (40~80. ^/8). The injection pressure should be appropriate. When the product is too large, it is easy to overflow edge, and the internal residual stress is large; the thick wall is easy to shrink and dent, so about 49MPa is generally selected. The temperature of the injection material is slightly lower than that of the pure PP powder, because the processing temperature of SBS is lower (160~190)

-

Plastic Injection Mould Motorcycle Parts Mould Motorcycle Fender Mould

The mud plate is a plate structure installed behind the outer frame of the wheel, usually made of high-quality rubber material, but also using engineering plastics. The fender is usually mounted on a metal baffle, cowhide baffle, plastic baffle, and rubber baffle behind a bicycle or motor vehicle wheel.

-

Injection Plastic Car Bumper Bracket Mould

Product Description Model NO. LA23-002 Application Auto parts mold Runner Hot Runner/Cold Runner Design Software UG Installation Fixed Certification TS16949, ISO Trademark LA Customized Customized After-sales Service 1year Transport Package Wooden Case Specification HS Code 8480719090 Origin China, Zhejiang, Taizhou Production Capacity 650 Set/Year Mold Traits There are several areas to note when designing and ...