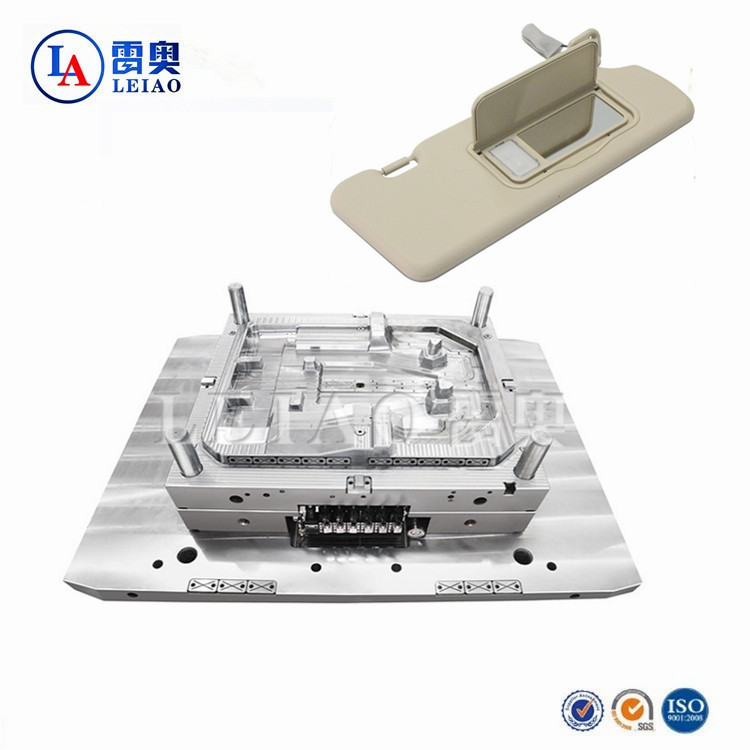

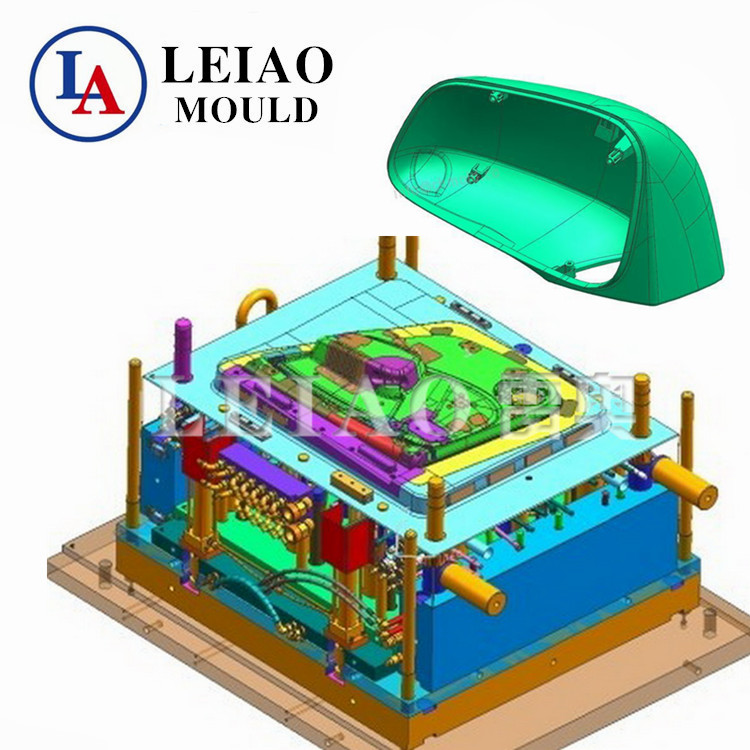

Injection Car Lamp Plastic Cover Auto Lamp Mould

Product Description

|

Model NO. |

LA22-118 |

Application |

Car |

|

Runner |

Hot Runner |

Design Software |

UG |

|

Installation |

Fixed |

Certification |

TS16949, ISO |

|

Trademark |

LA |

Customized |

Customized |

|

After-sales Service |

1year |

Transport Package |

Wooden Case |

|

Specification |

2400*1150*1400mm |

HS Code |

8480719090 |

|

Origin |

China, Zhejiang, Taizhou |

Production Capacity |

650 Set/Year |

In the design process of automobile lamp injection molding mold, Leo company will help customers to reasonably adjust the product wall thickness, and explore a better balance between product quality and production cost. Predict the appearance of fusion mark, gas mark, gas trapped and other defects, predict and control on the mold. Predict the product deformation, help customers to improve the product assembly structure, pre-design to avoid deformation. Reasonable arrangement of glue and cooling system, to achieve a better process effect and more economical input. Provide optimized production process parameters to help customers to solve the product injection molding production problems.

Mold Traits

There are several areas to note when designing and making fan leaf molds.

1

Non-appearance parts, the appearance surface of plastic parts does not allow spots, shrinkage and depression. Meluse marks. Flying side and other defects (appearance shrinkage requirements are not very high)

2

Plastic parts are internal function parts, with lamp head holes. Rear cover hole and other assembly requirements are high

3

The shape of the plastic parts is complex, and there are 6 inversions on the outer side of the plastic parts. Except for the lamp head hole, which is not the left and right mirror image, all the other features are the left and right mirror image

4

There are 6 backversions on the outer side of plastic parts, and lateral core structure should be adopted

5

According to the characteristics of the plastic parts, the plastic parts of the lamp shell have the risk of adhesive mold, and the design of the plastic parts should prevent the adhesive mold.

Why choose Leiao Mould for the production of household Mould?

Leiao Mould is a one reliable and professional high quality custom plastic mould manufacturer engaged in mould design,manufacturing & produce a variety of plastic injection moulds.We have a mature team of highly skilled designers, Engineers, Project Managers and Fabrication Technicians that ensure strictly control all of the project success.

The company specializes in plastic mold manufacturing, and has many years of experience in mold making, mainly manufacturing and processing medium and large injection molds, automobile interior and exterior trim molds, PET bottle blank molds, injection bottle cap molds, blow molds, chair stool molds, etc.It has its own unique processing technology in needle valve hot runner system mold, which is a cooperative enterprise worthy of your trust.