Welcome to our websites!

News

-

Smart toilet seat mold manufacturing precautions.

Existing intelligent toilet lid mold mostly use single layer mold processing, but when need mass production, the traditional single layer mold because of its low efficiency, not timely produce products, meet the expected output, production efficiency is low, and even reduce the turnover caused se...Read more -

How to control the quality of the plastic mold in the trash can?

The production requirements of plastic trash can mold are very high, generally using environmentally friendly pp materials,Can hit a bright surface and then do film printing and other processing, become a high-grade trash can,But it is not easy to make a good trash can. First of all, the quality ...Read more -

Why do we have to try the mold after the mold is processed?

After the injection mold is processed, the mold test is the last check step. Whether the mold can produce qualified products, you will know all about it. It can be said that the test model is a comprehensive test of our mold development and design, and the results of the test model will directly ...Read more -

How to customize the plastic injection mold?

Custom plastic injection molds requires the following information: 1. The necessary information Mold cavity number Plastic type (preferably model and MFI) Type of selected steel material (or inform the surface requirements of plastic parts and the amount of plastic products that the mold is inten...Read more -

Talk about the reasons and solutions of excessive burr of injection molding products

Product burr (flying edge) is a common injection problem, but also very easy to injection problem. The most important part of the flying edge is the processing of the classification surface, that is, between the moving mode and the static mold, the sliding matching part of the slider, the coordin...Read more -

What are the advantages of daily necessities mold?

Many daily necessities used by people are processed through molds. It only needs to adjust the material according to the proportion and directly inject it into the mold. After its molding, the mold can directly complete the production of daily necessities. Then what are the advantages of daily ne...Read more -

Method of making the bottle cap mold

With the development of economy and the prosperity of the market, the variety of pre-packaged food is more and more rich, all kinds of products as stars. Among them, many food packaging containers use sealing cover to achieve sealing, in order to ensure its sealing effect, to ensure that there wi...Read more -

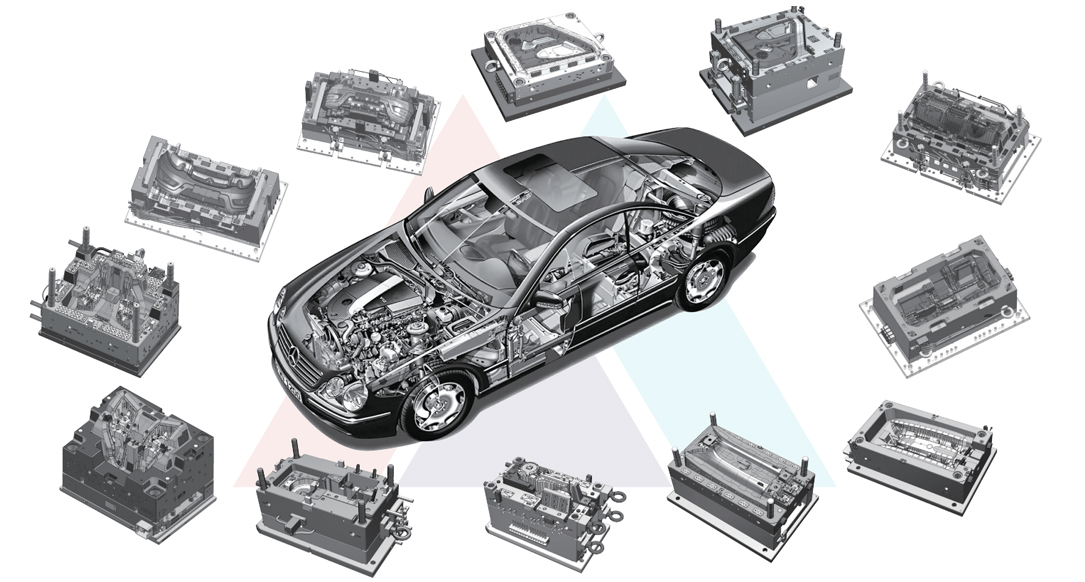

Do you really know anything about car molds?

In recent years, with the rapid development of China’s automobile industry, the automobile mold industry has also been greatly developed. Automobile mold is a technical product and a typical customized product, especially the technical content of automobile cover mold is very high. Therefor...Read more -

How to avoid dimensional instability of injection molded products?

In the mass production of products, dimensional instability is a process situation that is more likely to occur. If it can be avoided in advance, it can save a lot of costs and avoid unnecessary waste. 1. Definition of dimensional instability Dimensional instability refers to the change of produc...Read more -

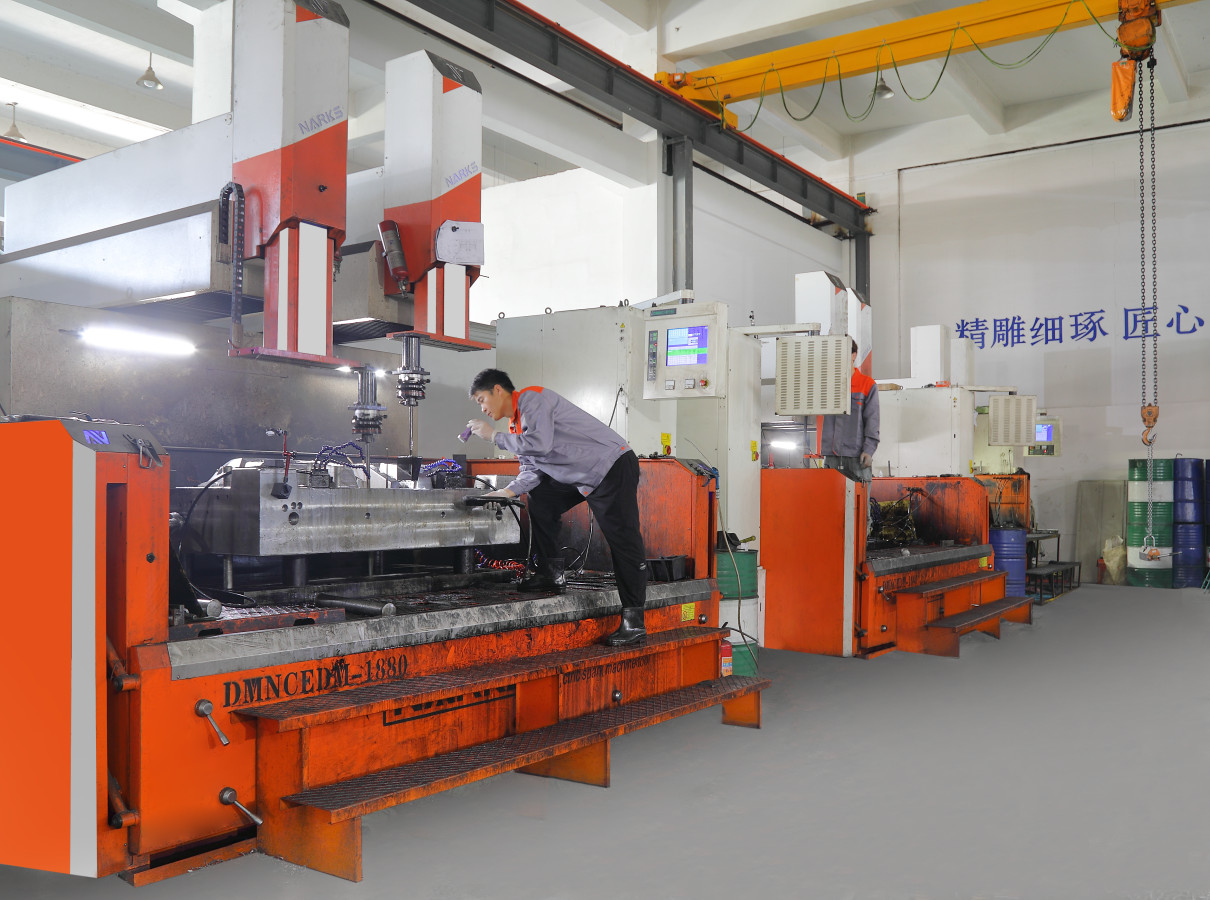

Reliable automotive lamp mold supplier

Do you want to work with a reliable automotive mold supplier?Leiao Mold will be your reliable partner.We have extensive experience in manufacturing various auto parts molds,For example, the car lamp mold, with high appearance requirements, several important parts are transparent parts, electropla...Read more -

What are the differences between blow molding and injection mold? How much do you know about that?

Today introduced the two mold production processes, the production of products is full of our life everywhere, is injection molding and blow molding two processes. They have their own characteristics, blow mold using the “injection + blow”, injection mold using “injection + pres...Read more -

Industry of the trash can mold solution

According to the different scope of use, the trash can can be divided into household and industrial items.Leiao has accumulated rich experience in the mold manufacturing of trash cans, and has developed different capacity and different styles of trash cans for customers in different countries, su...Read more