Welcome to our websites!

News

-

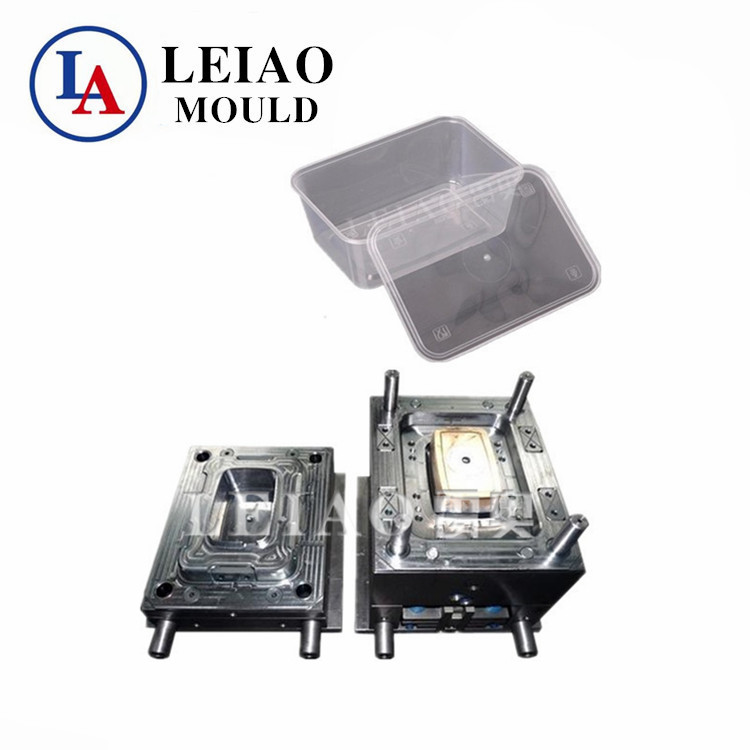

How to solve the deformation problem of thin-wall plastic products?

Professional thin-walled mold manufacturers teach you thin-wall plastic products deformation solutions as well as thin-walled box molds, IML thin-wall products, thin-wall products injection molding process. Thin-wall plastic products have high requirements on the size of thin-wall molds and the p...Read more -

Eight categories of injection molds

(1) Single-type surface injection mold When the mold is opened, the moving mold and the mold are separated, so as to take out the plastic parts, called single type surface mold, also known as double plate mold. It is the simplest and the most basic form of injection mold, according to the need ca...Read more -

The cause of the injection mold rust and the solution

Mold rust is a relatively obvious phenomenon, it not only affects the appearance of the mold, but also will directly affect the overall quality of the mold, so the mold rust is a problem that can not be ignored, the following is the analysis of the reasons and measures, for your reference. The ca...Read more -

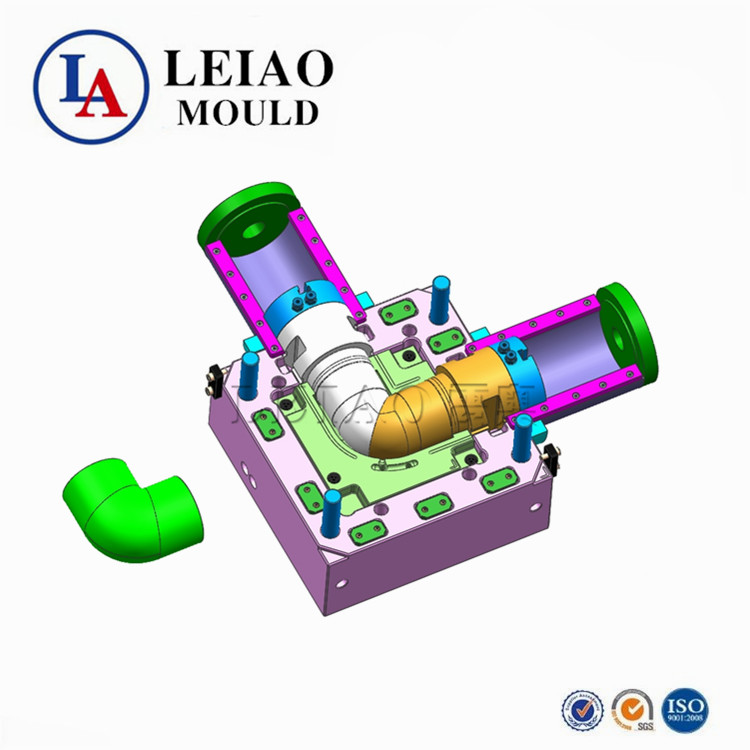

How to make a good pair of pipe fittings mold?

I believe that we are familiar with the plastic pipe fittings, which can be used as a drainage pipe, water supply pipe, mining pipe, communication pipe, the application range is very wide. Leiao, as a supplier with more than 10 years of experience in pipe fittings mold manufacturing, provides var...Read more -

Advantages of the Leiao bottle cap mold

Leiao mold professional provides a complete range of bottle cap molds, we have a complete research and development team, design department, high precision processing equipment, quality inspection department and after-sales service team, to ensure the excellent quality of each bottle cap mold rece...Read more -

How to make a high quality helmet mold?

Safety helmet is a line of defense to protect the life safety of battery car and motorcycle drivers. Do you want to produce high quality helmet mold? Just look for the Leiao mold. Over the years, the domestic and foreign helmet manufacturers have supplied a large number of reliable plastic helmet...Read more -

Basic specifications and characteristics of plastic paint bucket molds

Due to the different market demand, there are many kinds of plastic paint bucket molds, including shape, material, size and appearance.for instance:Material: New or recycled polypropylene (PP), polyethylene (PE) material. Shape: round, oval, square, rectangular… Size: from 1L to 30L… ...Read more -

What are the requirements for injection molds?

The working conditions of Plastic Injection Moulding are as follows: 1. Wear resistance When the blank is plastically deformed in the cavity of the injection mold, it both flows and slides along the surface of the cavity, causing severe friction between the surface of the cavity and the blank, re...Read more -

Introduction of pipe fittings die and the selection of steel material of pipe fittings die

Plastic pipe fittings mold: As the name suggests, it is used to make plastic pipe fittings on the injection molding machine. This model is usually formed by processing and grinding with special steel. The quality of a plastic pipe mold, mainly depends on the plastic pipe mold production process. ...Read more -

Injection mold mirror polishing knowledge

(1) manual operation mechanical polishing: is by cutting, material surface plastic deformation removed after polishing the convex and smooth surface polishing method, generally use oil, wool wheel, sandpaper, etc., is given priority to with manual operation, special parts such as rotary surface, ...Read more -

How to make a good pair high quality helmet mold?

The quality of the main helmet cap shell is related to the life safety of drivers and passengers. The plastic cap shell mold developed by the Leiao plastic mold design team has high quality, high efficiency and high speed, which can solve the problem of production efficiency for customers. We opt...Read more -

How to make the plastic coat hanger mold?

The hanger mold is an important factor in the hanger shape and quality. The hanger mold in the mold classification is almost all classified as the injection mold classification, mainly related to the processing and use of the mold. Specifically, the heat-melted material is injected into the hange...Read more