Plastic Household Mould

-

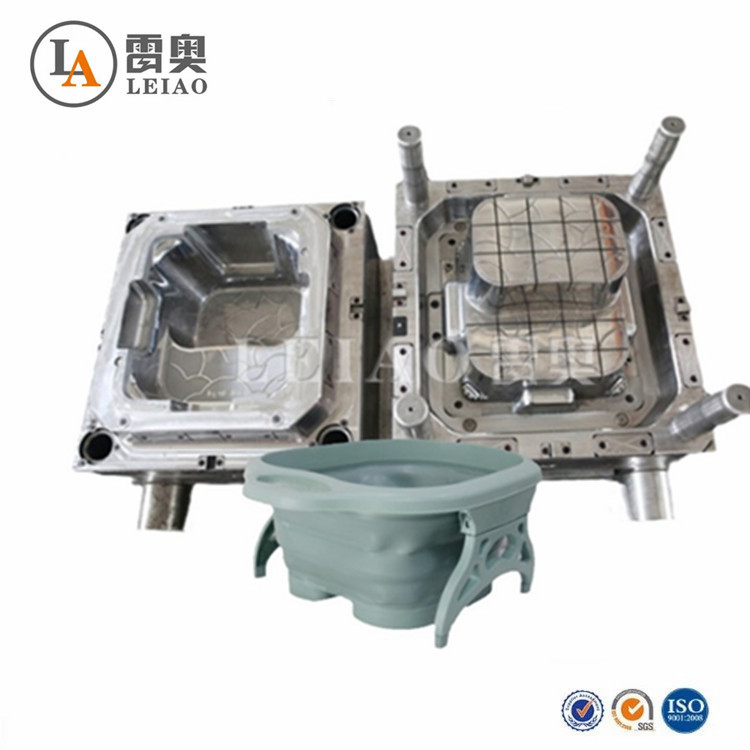

Hot Sale Plastic Injection Molding Foot Bath Tub Foot Washing Tub Mould

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.

-

Customized PP/ABS/PC Plastic File Box Mould with Low Price

Leiao Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

-

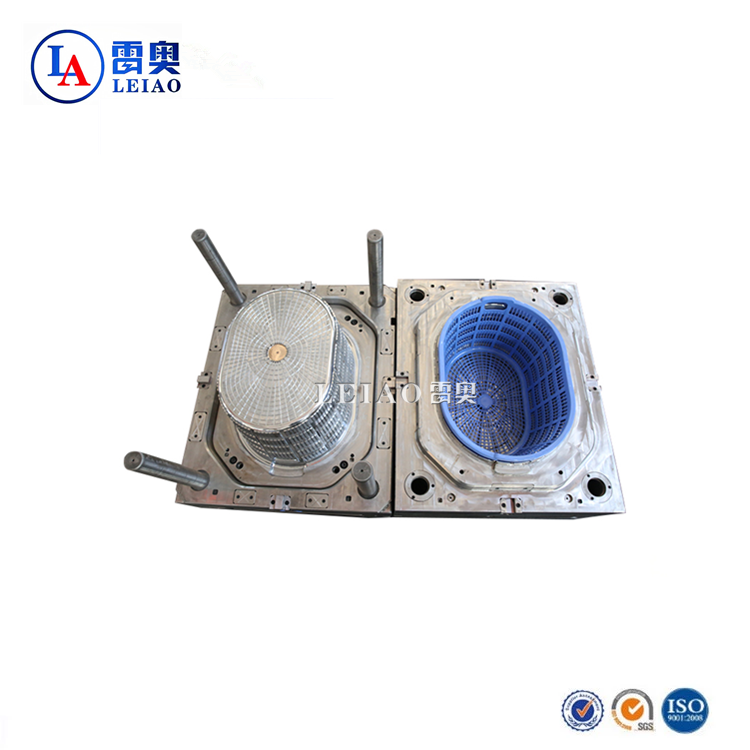

Customized PP Dirty Clothes Laundry Basket Mould Plastic Injection Mold

Leiao mold enjoys excellent experience and specializing variety of wholesale Plastic Crate Moulds such as milk boxes mould , fruit and vegetable Mould, bottled turnover boxes, heavy turnover boxes, aquatic products boxes, pallet boxes, Folding turnover box, etc.The mould standard is completely customized based on customers’ requirements and can realize interchangeable designs such as height,bottom, size etc..

-

PP/PC Plastic Chair Mould Household Injection Chair Mold with Arm

Chair Mould Advantages:

PC ghost chair mould, gas assisted chair mould, beach chair mould,leisure chair mould, rattan chair mould etc.Every year produce more than 200sets of chairs.Interchangeable insert block different versions of chair backrest & backrest inserts can be easily replaced on the machine.

Cycle time 35 to 40 seconds for high speed running cycleTop quality Chinese chair moulds manufacturer

-

Plastic Pail Bucket Mould Injection Mould Bucket Paint Bucket Mold 20lts

Plastic bucket mold is a very widely used mold, mold using high-speed lathe processing, high precision, long life, the bucket can be made in commercial, domestic, industrial and other places, suitable for indoor and outdoor use.

Robust construction, enhanced edges to provide superior structural integrity and a firm lid -

Customized Folding Children Dining Chair Mould Baby High Chair Mould

The advice to customers on choosing plastic materials for children’s dining chair moulds from Leiao is not necessarily the best, but it must be cost-effective. In the manufacturing process, a special hot runner system is adopted to assist the moulding, so that the cost of the children’s dining chair will be reduced in terms of production efficiency.

-

Customized PP Dirty Clothes Laundry Basket Mould Plastic Injection Mold

Leiao Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

Our mould include a different range of molds such as table molds, bucket molds, basket molds, dustbin molds, storage box molds, baby bathtub molds, flowerpot molds, crate molds, washbasin molds, chair molds, drawer molds, stool molds, baby set molds, laundry basket molds, pallet molds, trash can molds, spoon molds, knife molds, fork molds, thin wall box molds, and cap molds. Our team of highly skilled technicians and engineers is dedicated to designing and producing molds that meet the most demanding specifications.

-

Plastic Shoe Box Injection Mould Storage Box Mould

Choose different steel according to plastic product material,mould life and customers requirements.

We all buy mould raw material from large metal companies.

We personally test the hardness of the mould steel.

There are strict inspection procedures for the hardness of mould steel,and mould life is 300000 to 3 million shots.

-

Plastic Tool Box Mould

Plastic Tool Box Mould

-

Good Quality Plastic Flower Pot Mould

Leiao has been developing plastic flower pot moulds for many years. The flower pot moulds produced by Leiao are durable, and the mould structure design is reasonable and has a long service life. The movable parts of the mould are processed by the H13 vacuum quenching process, which can effectively solve the problems of mould flash and eccentricity. Leiao also develops various new flower pot moulds such as smart flowerpot moulds, lazy flower pot moulds, imitation rattan flowerpot moulds, etc.

-

Vegetable Basket Rice Washing Basket Plastic Injection Mold

Plastic basket mold is very common household mold, very widely used, mold using high speed lathe processing, high precision, long life, make the basket can be used in agriculture, commercial, household, plastic basket is very common in daily life, such as washing vegetables basket, dirty basket, shopping basket and so on have plastic material, all belong to the plastic basket. It can be seen that the wide application of plastic baskets.

-

PP PC Plastic Chair Mould Household Injection Chair Mold with Arm

Chair Mould Advantages:

PC ghost chair mould, gas assisted chair mould, beach chair mould,leisure chair mould, rattan chair mould etc.

Every year produce more than 200sets of chairs.

Interchangeable insert block different versions of chair backrest & backrest inserts can be easily replaced on the machine.

Cycle time 35 to 40 seconds for high speed running cycle

Top quality Chinese chair moulds manufacturer