Products

-

OEM/ODM Plastic Dog Cage Injection Pet Product Mold/Mould

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.

-

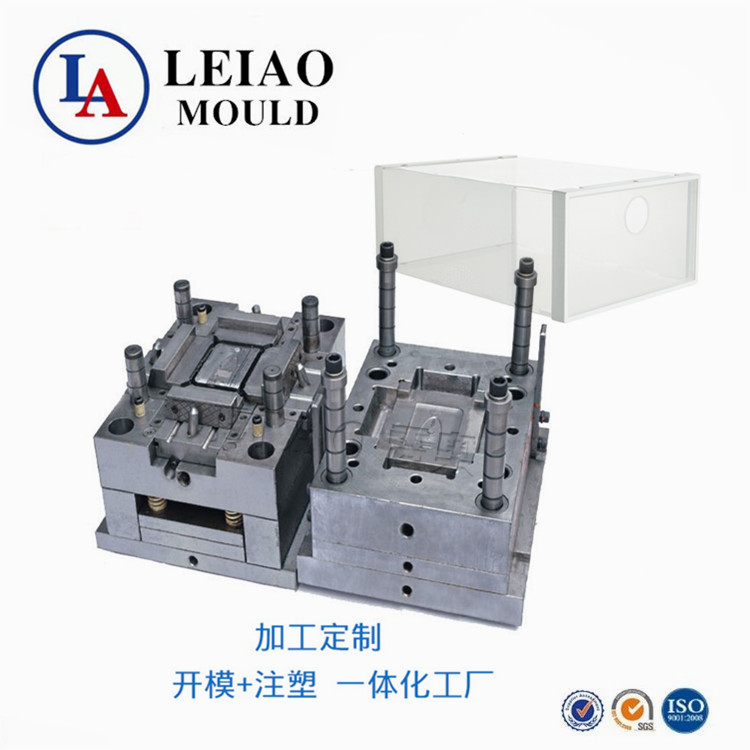

Injection Mould for Stackable with Wheels Plastic Foldable Storage Box

Leiao Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

-

Injection Household Clothes Plastic Folding Storage Box Mould with Lid

re household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.

-

High quality foldable shopping cart mold folding luggage cart can be customized open mold

- Foldable Design to Save Space: This shopping cart with a hanging lid can be easily folded into a flat shape and is easy to

store in the trunk, corners and garages. The utility cart weighs only 9 lbs, so it can be easily carried by hand. To transform it into a box shape, you just need to unfold it and slide the lock to fix it. - Easy-to-climb Rear Wheels: The rear wheel is designed with oversized tri-wheels to easily go up or go down the stairs. When climbing stairs, there is no need to carry the shopping cart by hand. In order to maintain the service life of the cart, we recommend that the shopping cart must be in front of people when going down the stairs.

- Lockable 360° Swivel Front Wheels: This foldable trolley comes with front wheels that can rotate 360° without noise to achieve better control and change directions smoothly. What’s more, the front wheels feature lockable design that can prevent the car from sliding effectively when not in use.

- Multiple Purposes for Use: This durable multifunctional trolley box can be served as a shopping cart to load fruits and

vegetables or carry many heavy items when shopping. Apart from this, it can not only be used as a step stool for easy access to high objects, but also as a chair to provide a stable seat for you to rest.

- Foldable Design to Save Space: This shopping cart with a hanging lid can be easily folded into a flat shape and is easy to

-

High quality plastic injection molding automobile mold

1. Start from part design analysis.

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3. If product is complex, moldflow report will be present as well.

4. Indoor workshop ensures you high quality under good control.

5. Normally it takes 15-60 days to make mold, precise time depends on complexity of design.

-

Toy Car Plastic Injection Mould for Kids Toys

Our kids electric car mould is highly flexible and customizable. We can create toy cars of any brand, size, shape, or design to precisely fulfill your needs. Our expert team collaborates with you to ensure a hassle-free and seamless manufacturing process. By employing the latest technology and techniques, our mould consistently generates high-quality and precise outcomes.

-

OEM Experienced Injection Plastic Auto Car Bumper Mould/Mold

Advanced internal parting surface technology is usually adopted in the design of Auto bumper mould. The advantage is that the parting line is hidden on the non-appearance surface of the bumper, and the parting line cannot be seen after being assembled on the car, which will not affect the appearance of the product. However, the difficulty and structure of this technology are more complicated than that of the outer parting type bumper, and the technical risk is also higher. The cost and price of the Auto bumper mould will also be much higher than that of the outer parting type bumper. It is widely used in high-end cars.

-

Multi Cavity Plastic Hair Comb Injection Mould Plastic Mold for Comb

Leiao Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

Our mould include a different range of molds such as table molds, bucket molds, basket molds, dustbin molds, storage box molds, baby bathtub molds, flowerpot molds, crate molds, washbasin molds, chair molds, drawer molds, stool molds, baby set molds, laundry basket molds, pallet molds, trash can molds, spoon molds, knife molds, fork molds, thin wall box molds, and cap molds. Our team of highly skilled technicians and engineers is dedicated to designing and producing molds that meet the most demanding specifications.

-

Customized 20 Inch 24inch 28inch Luggage blow molding mold

Good blow molding luggage mould design is the first step,Leiao mould has 3 designers with more than 15 years experience.

1:We will analyze the feasibility,shrinkage and molding temperature of plastic products.

2 :We will communicate with customers,including details such as weight,style design,size and appearance,stability and wear resistance of plastic products.

3:Design and mold flow analysis are provided free of charge.

-

Plastic Shoe Storage Box Mold Maker Sneaker Box Mould

This product are made according to the customer, the copayright belongs to the customer, here only to prove that we have the ability to product.

-

plastic luggage mold

Good injection luggage mould design is the first step,PRC mould has 3 designers with more than 15 years experience.

1:We will analyze the feasibility,shrinkage and molding temperature of plastic products.

2 :We will communicate with customers,including details such as weight,style design,size and appearance,stability and wear resistance of plastic products.

3:Design and mold flow analysis are provided free of charge. -

Plastic Kitchen Wash Vegetable Fruit Drain Storage Basket Injection Mould

We are experienced with various plastic injection molds. This group includes plastic injection moulds for daily use, such as plastic cup mould, hanger mould, dustbin mould, basket mould and so on.