Products

-

OEM Car Interior Accessories Injection Mold Company Plastic Automobile Dashboard Mould

The instrument panel is a very unique part of the car, integrating safety, functionality, comfort and decoration. The main die drawing direction of the instrument panel is determined according to the outer surface of the instrument panel and the air outlet position. It is generally between 20 degrees and 30 degrees, and the die drawing direction of the secondary instrument panel is vertical; the direction of the outer surface of the instrument panel is at least 7, which shall be determined on the depth of the surface skin pattern of the instrument panel. The drawing angle of the invisible area should not be less than 3. If less than 3, the surface of the parts may produce other marks, because the use of slider will first affect the appearance of the parts, and then affect the life of the mold, and the mold cost will increase accordingly.

-

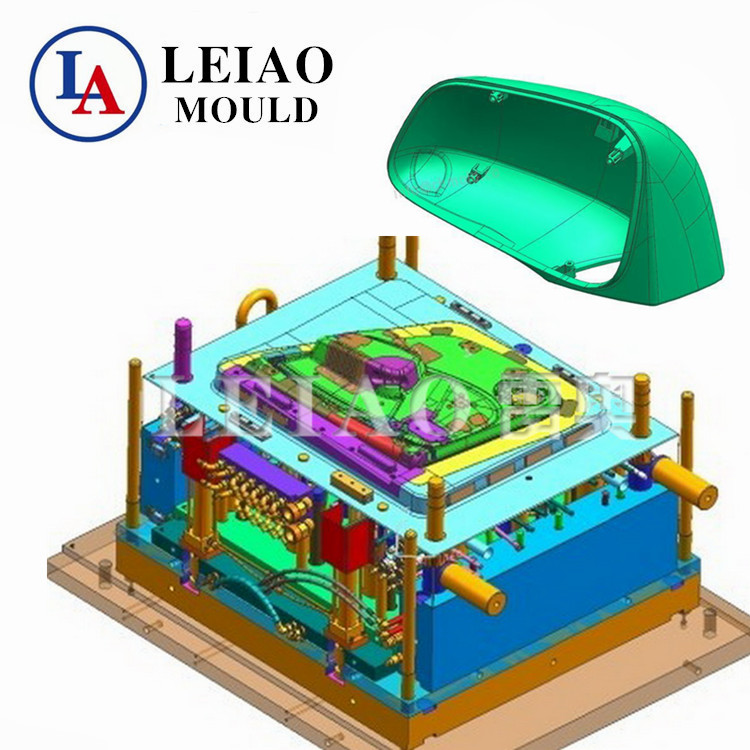

Factory Price Customized Auto Parts Rearview Mirror Mold of Plastic Auto Parts Mold

During the injection molding process, the cavity of the mirror shell mold will be affected by high pressure, so the mirror shell mold cavity should have sufficient strength and stiffness. Insufficient strength will lead to plastic deformation and even cracking; insufficient stiffness will lead to elastic deformation, leading to the outward expansion of the type cavity and the overflow gap. Due to the large size of the mold cavity of the automobile rearview mirror shell, the internal stress of the cavity often exceeds the allowable stress before the large elastic deformation, so the strength of the cavity should be checked.

-

Injection Plastic Car Bumper Bracket Mould

Product Description Model NO. LA23-002 Application Auto parts mold Runner Hot Runner/Cold Runner Design Software UG Installation Fixed Certification TS16949, ISO Trademark LA Customized Customized After-sales Service 1year Transport Package Wooden Case Specification HS Code 8480719090 Origin China, Zhejiang, Taizhou Production Capacity 650 Set/Year Mold Traits There are several areas to note when designing and ... -

PP Flowerpot Tray Plastic Mould Design Manufacture Flowerpot Rack Mold

Plastic flowerpot is a kind of flowerpot made of plastic, which is more commonly used in people’s life. Compared with the traditional porcelain flower pot, watering less times, the price is relatively cheap, accidentally destroyed, durable. With the progress of society, people’s living standards continue to improve, the need to be more ideal than the traditional flower pot, a multi-purpose plastic flower pot, such as rectangular flower pot, wall hanging flower pot, hanging basin, function and water storage flower pot, automatic watering flower pot, water detection and so on. Plastic pot is low price, high practicality; light texture, easy to carry; not easy to break the essence, more durable; and easy to clean.

-

Plastic Injection Mould for Beach Chair Garden Chair Stackable PP Plastic Outdoor Dining Room Chair for Dining Table Set

A pair of high quality beach chair mold has an important relationship with its mold structure form, and the classification surface is an important factor to determine the mold structure form, and is also closely related to the overall structure of the mold and the mold manufacturing art. The classification surface directly affects the flow characteristics of plastic melt and plastic demolding. Design of classification surface: because the typing surface is affected by the molding position in the mold, the design of pouring system, plastic structure process and precision, shape and destruction method, mold manufacturing, exhaust, operation process and other factors, so the selection should be comprehensively analyzed in the selection of classification surface.

-

High Quality Plastic Banana Box/Crate Mould

Plastic turnover basket main material is made of PE material, through the injection molding process integrated molding of plastic products, the overall durable, with strong tenacity, throw is not easy to damage, widely used, common in all walks of life transportation turnover, packaging damage prevention, storage and storage, production line classification and so on.

-

Custom Plastic Home Use Basket Injection Mold Supermarket Use Plastic Basket Plastic Injection Mould Injection Molding

Plastic basket mold is very common household mold, very widely used, mold using high-speed lathe processing, high precision, long life, make the basket can be used in agriculture, business, household, plastic basket is very common in daily life, such as washing vegetables basket, dirty basket, shopping basket and so on have plastic material, belong to the plastic basket. It can be seen that the wide application of plastic basket.

-

Plastic Injection Mold ABS Smart Toilet Seat Mould

Make toilet seat mold mold steel to choose first, actually to find the mold factory, Leiao company produces intelligent toilet lid mold generally using PP or ABS material, mold surface finish is high, can not have fly side burr, steel in Sweden s136 or Japan Datong NAK80 steel, product assembly accuracy is very high, must use high-speed milling machine even 5 axis high-speed milling processing.But the better the mold, the higher the maintenance requirements, Take the Japanese TOTO toilet mold produced by our Leiao mold and Panasonic as an example, intelligent toilet seat mold used for a long time without the correct maintenance, proper maintenance of mold compared to not maintenance mold, can get longer service life, lower failure rate and higher product yield, for injection molding products processing enterprise is very effective way to reduce the cost, increase efficiency.

-

Air Conditioning Outdoor Shell Injection Mould

Analysis of key points of air conditioning mold. The analysis of the uneven air conditioning wall thickness caused by the eccentric air conditioning die is as follows:

1.If the cooling water flows uneven in each area of the core cavity of the air conditioning mold, it will cause the flow difference of melting plastic, the hotter the area will be greater, the colder the area will be smaller, thus making the air conditioning wall in the hot area a little thicker. Under normal conditions, different temperatures will cause at least 0.05mm tolerance.

2.Generally speaking, the zero degree four-Buick lock height of the air conditioning mold should be 20% -30% of the height of the plastic air conditioning mold, such as the smaller air conditioning mold should be 20%, and the larger air conditioning mold should be about 30% height.3. When we do the air conditioning mold type core cavity processing, we should pay special attention to the selection of processing equipment. -

Custom Auto/Car Front Grille Plastic Injection Mould

The size of automobile grid die is large, and the back die has more flat top or small diameter ejector pin, so it is difficult to process, so it needs to be mosaic treatment.

-

Home Appliance Customer Design Hot Selling Electric Table Fan Mold

Mold traits:

Electric fan leaf mold products are small, using three board mold, 4 needle point pouring port glue. Fan blades belong to a large group of molds, divided in the front and rear mold insertion between the blades, on the premise of ensuring the sealing area, the insertion Angle as far as possible, to prevent the insertion Angle is too small and burning. Mold is cooled by circular cooling. -

OEM Experienced Injection Plastic Auto Car Bumper Mould/Mold

Product Description The automobile lamp mold includes headlight mold and taillight lens mold, etc. The previous CAE analysis is used to predict the molding pressure, reduce the actual molding pressure and reduce the adhesive front mold; for the automobile lamp headlight BEZEL, through the previous CAE analysis, the automobile lamp is very high, so the mold needs to be polished to the mirror. In the design process of automobile lamp injection molding mold, Leo company will help customers to re...