Products

-

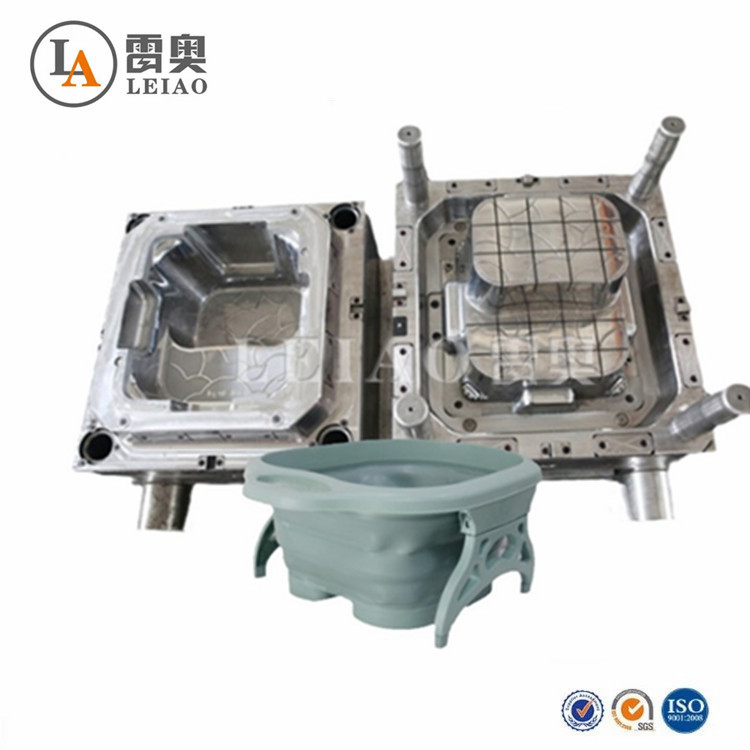

Hot Sale Plastic Injection Molding Foot Bath Tub Foot Washing Tub Mould

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.

-

Customized PP/ABS/PC Plastic File Box Mould with Low Price

Leiao Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

-

Blow molded bus seats

eat plate backrest: The seat plate and backrest are made of high-quality HDPE (polyethylene) blow molding, which is integrally formed. The plastic parts have more stable structure and higher strength; Adopt environment-friendly color masterbatch and stabilizer, with strong UV resistance and flame retardancy.

-

Sport Center Seats Blow Molded Cheap HDPE Plastic Chairs Without Armrest

Leiao’s blow molded stadium seats, including single blow molded seat and tip-up seat, are designed and produced according to the highest relative international standard, provides various floor seating options to suit specific needs and requirements. Blow molding seats have been proved to suit all tough weather situation, making it wildly used in stadium & area.

-

Plastic Mould for Pipe Fitting

Good PVC mould design is the first step,Leiao mould has 3 designers with more than 15 years experience.

1:We will analyze the feasibility,shrinkage and molding temperature of plastic products.

2 :We will communicate with customers,including details such as weight,style design,size and appearance,stability and wear resistance of plastic products.

3:Design and mold flow analysis are provided free of charge.

-

Customized PP Dirty Clothes Laundry Basket Mould Plastic Injection Mold

Leiao mold enjoys excellent experience and specializing variety of wholesale Plastic Crate Moulds such as milk boxes mould , fruit and vegetable Mould, bottled turnover boxes, heavy turnover boxes, aquatic products boxes, pallet boxes, Folding turnover box, etc.The mould standard is completely customized based on customers’ requirements and can realize interchangeable designs such as height,bottom, size etc..

-

Pet Feeder Mould

The pet product mould is usually composed of multiple parts, and the appearance needs to be sun-textured. Plastics are generally made of PP or ABS materials. At the beginning of the design of each pet product mould, the mould opening direction and parting line must be determined first to ensure that the core pulling mechanism is minimized and the influence of the parting line on the appearance is eliminated as much as possible. So pay attention to the main points.

1. After the mould opening direction is determined, the reinforcing ribs, buckles, protrusions and other structures of the product are designed to be consistent with the mould opening direction as much as possible, so as to avoid core pulling and reduce seam lines and prolong the life of the mould.

2. For example: the mould opening direction of the pet feeder mould is generally the χ direction of the body coordinate. If the mould opening direction is designed to be inconsistent with the χ axis, the angle must be indicated in the product drawing.

3. After the mould opening direction is determined, an appropriate parting line can be selected to improve the appearance and performance.

Leiao has made pet product moulds for hundreds of companies around the world. In addition to making moulds, we can also provide customers with better product design solutions. -

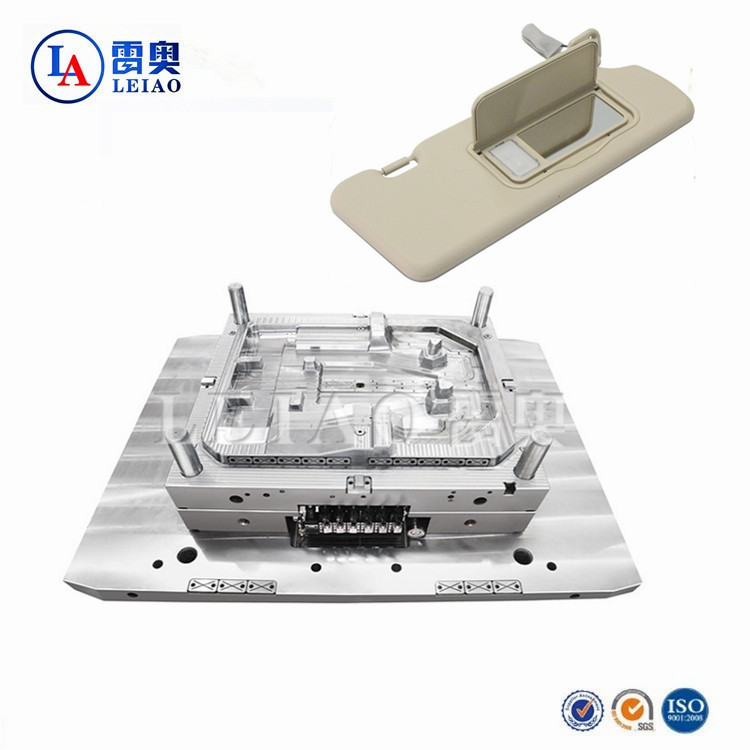

Plastic Injection Auto Door Visor Mould

Plastic Injection Auto Door Visor Mould

-

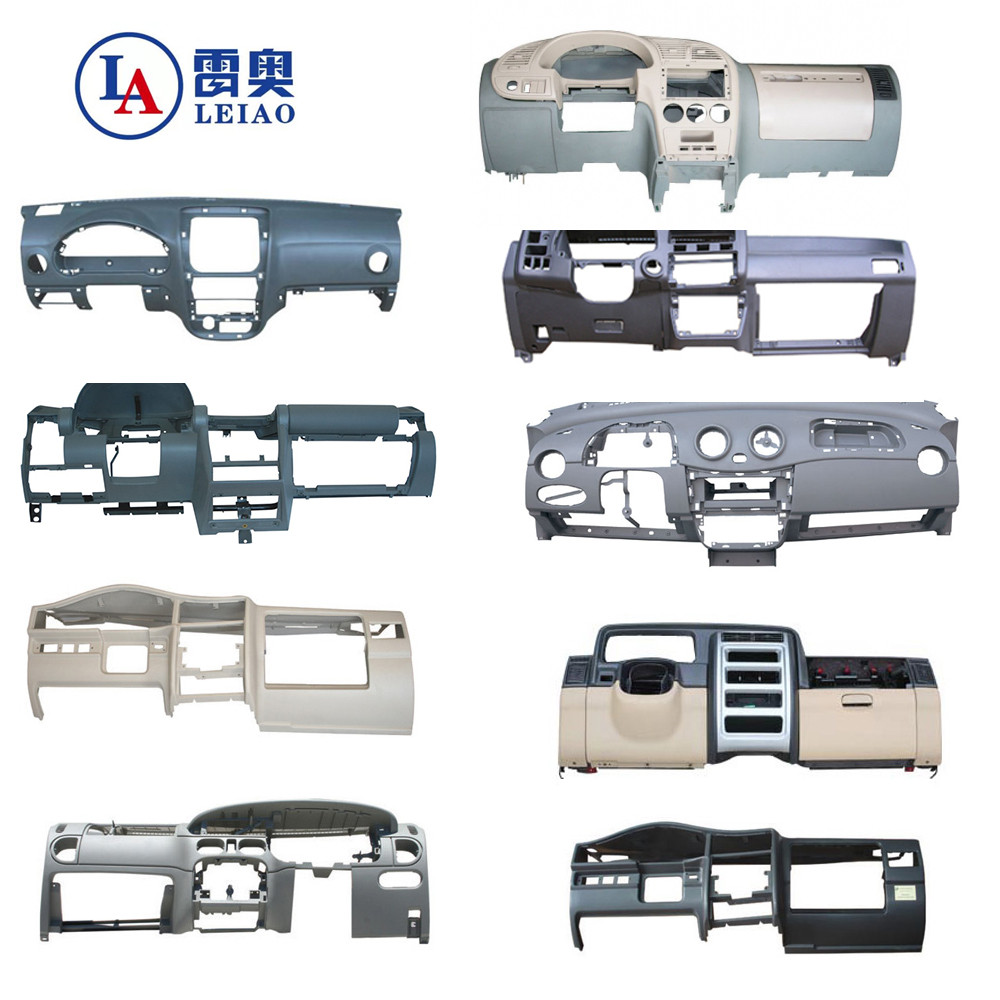

Auto Parts Car Dashboard Mould Plastic Injection Mold Moulding Molding

Professional plastic mold, plastic injection mould customization, rich experience, welcome to inquire at any time

-

PP/PC Plastic Chair Mould Household Injection Chair Mold with Arm

Chair Mould Advantages:

PC ghost chair mould, gas assisted chair mould, beach chair mould,leisure chair mould, rattan chair mould etc.Every year produce more than 200sets of chairs.Interchangeable insert block different versions of chair backrest & backrest inserts can be easily replaced on the machine.

Cycle time 35 to 40 seconds for high speed running cycleTop quality Chinese chair moulds manufacturer

-

Car Central Control Panel Mould Manufacture Auto Part Mold

We have been engaged in plastic mold and plastic products export services, we have been engaged in this service for 10 years, our clients come from many countries, like United States, United Kingdom, Spain, Australia, Singapore, Russia, Japan, etc.

-

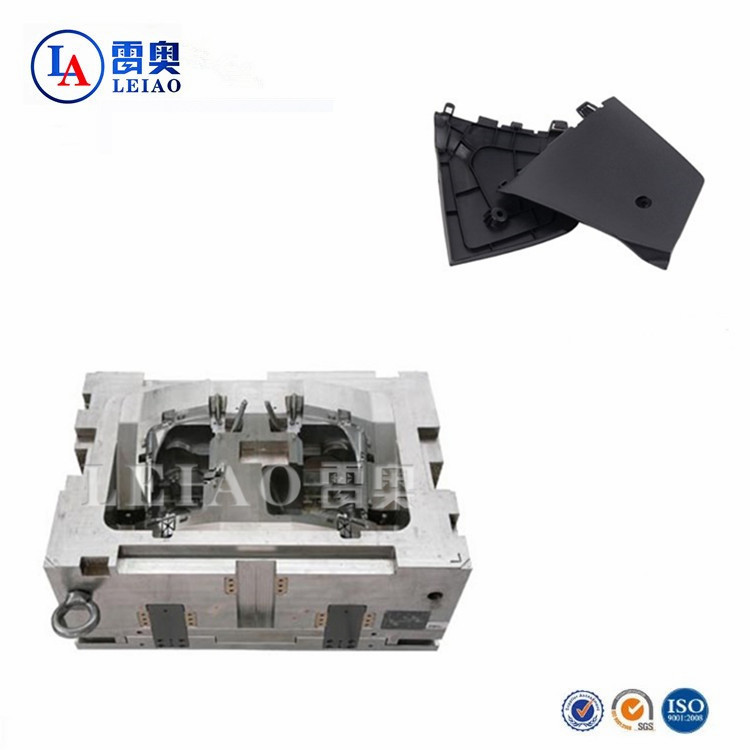

Taizhou Auto Exterior Parts Wiper Mould Plastic Injection Mold Maker

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are car parts mold,household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.