Products

-

Car Windshield Wiper Blade Mold Plastic Auto Windscreen Wiping Blades Injection Mould

1. The speed of product ejection don’t be too slow, a little faster than normal speed to make the ejection plate in place.

2. Advising to use Robot Hand to pick products to ensure mould safety, because there are angle lifts and other complex structures.

3. Advising to use PA66+30%GF raw material to produce, which has good hardenability and toughness with a long lifetime; but PBT+30%GF raw material is soft and crisp, which is easily broken. -

Custom Plastic Injection Mould for Rattan Chair /Household Chair

Custom Plastic injection mould for Rattan Chair /Household Chair

1. Start from part design analysis.

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3. If product is complex, moldflow report will be present as well.

4. Indoor workshop ensures you high quality under good control.

5. Normally it takes 15-60 days to make mold, precise time depends on complexity of design. -

Household Injection Plastic Long Handle Water Scoop Mould

Household Injection Plastic Long Handle Water Scoop Mould

Leiao Mould is a professional manufacturer of plastic injection mould in China. The main products are household plastic mould, home appliance mould, thin-wall mould, industrial mould, plastic chair mould,plastic crate mould, plastic bucket mold, trash can mold, etc.

If you are interested in our plastic injection mould, please feel free to contact us for inquiry, we can provide you with the perfect injection mould solution.

-

Plastic Flower Pot Injection Mold Plant Pot Injection Mould

Garden Mould – Plastic Flower Pot Mould

Plastic flower pots are becoming more and more popular, they are in light weight, cheap cost and colorful, also have many different amazing looking design, like rattan imitation, two color plastic pots, pots which can hanger on handrail or plafond.

Our factory has been involved in plastic flower pot mould manufacturing for more than 10 years. For this type of moulds, the structure is very simple, but usually customers have some special requests on flower pot design. At Leiao, we have a strong designer team, who work well on new prdocuts design and mould structure.

-

Customized Hot Runner Edible Oil Bottle Plastic Handle Injection Mould

Handle MouldThe handle has a side handle and a lifting handle on the neck of the bottle mouth, both to facilitate lifting the bottle. They are of various shapes and widely used, including those for mineral water, edible oil bottles, soy sauce and vinegar bottles, and paint barrels. Most of the handle molds need to be processed by wire cutting and fine carving. The mold is easy to form with good exhaust, and can provide customers with molds with high use value. -

Plastic Injection Mould for Hand Basket Plastic Supermarket Shopping Basket

1. Basket Size: 395*300*245mm

2. Basket Weight: 700g3. Basket material: PP4. Mould runner system: Hot runner or cold runner5. Mould cavity number: As per customers’ need -

Children Plastic Outdoor Slide Injection&Blow Mould

Introducing our Children Slide Plastic Mould, the perfect solution for creating fun and safe play equipment for kids! Our high-quality plastic injection mould is designed to accurately shape your creative ideas and designs into a durable and long-lasting product.

Crafted with precision and expertise, our plastic mould is made from top-grade materials to ensure maximum durability and strength. Whether you’re a playground equipment manufacturer or a DIY enthusiast, our injection mould is the perfect tool for creating custom-made slides that are safe, sturdy, and fun for kids of all ages.

With our plastic mould, you can easily create a variety of slide designs, from straight slides to spiral slides and everything in between. Plus, our mould is easy to use and requires minimal maintenance, making it a cost-effective solution for all your slide-making needs.

So why wait? Order your Children Slide Plastic Mould today and start creating the perfect play equipment for kids! With our mould, you can bring your creative ideas to life and provide children with a safe and enjoyable play experience. Don’t settle for anything less than the best – choose our plastic mould and see the difference for yourself!

-

Child Tricycle Injection Mould Plastic Baby Walkers Mold

To provide our customers a satisfactory plastic baby tricycle mould factory, we focus on each mould production process. We conduct technical analysis, DMF, discuss with customers and provide professional advice on 3D drawing to produce effective and efficient baby used mould.We use high precision high speed tooling CNC machine to get a prefect parting line of mould.

-

Plastic Baby Walker Mold

Good plastic baby walker mould design is the first step,PRC mould has 3 designers with more than 15 years experience.

1:We will analyze the feasibility,shrinkage and molding temperature of plastic products.

2 :We will communicate with customers,including details such as weight,style design,size and appearance,stability and wear resistance of plastic products.

3:Design and mold flow analysis are provided free of charge. -

Customized Injection Plastic Egg Tray Mould

Leiao mold enjoys excellent experience and specializing variety of wholesale Plastic Crate Moulds such as milk boxes mould , fruit and vegetable Mould, bottled turnover boxes, heavy turnover boxes, aquatic products boxes, pallet boxes, Folding turnover box, etc.The mould standard is completely customized based on customers’ requirements and can realize interchangeable designs such as height,bottom, size etc..

-

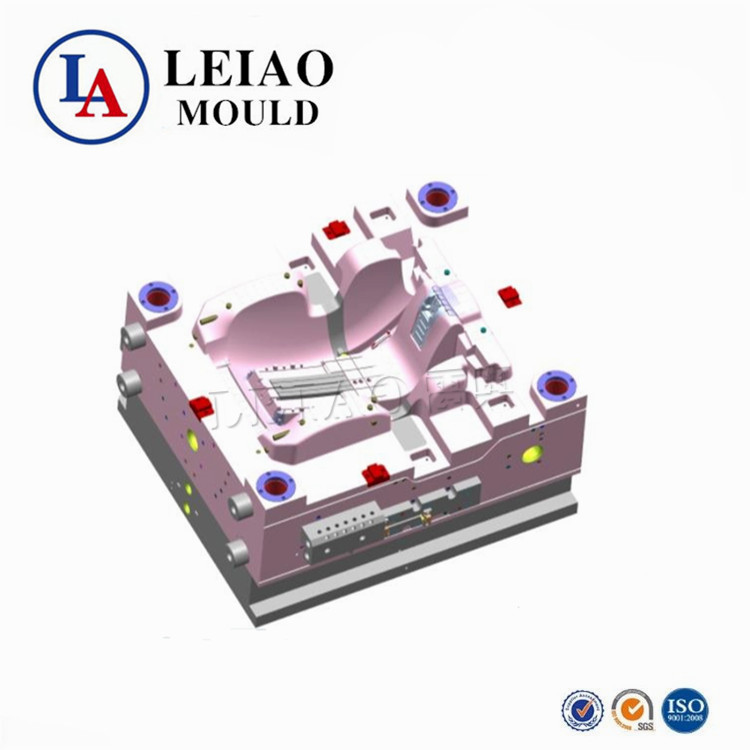

High-Quality Injection Mold for Child Safety Seat

Leiao Mold has rich experience in automotive parts, power tool parts, farming machinery parts, household appliances, child seat products molds manufacture and molding production.

-We have full set of advanced equipments: CNC High speed machining centers, EDMs, CNC lathes, Large milling machines, grinding machines, Deep-hole drilling machines.

-

Custom Baby Kids Infant Plastic Injectino Molding Bath Tub Mold Plastic Children Bathtub Mould

In order to let customers spend the most reasonable money to create the most satisfactory children’s bath bath mold! We rack our brains to make a set of high efficiency mold can save injection processing cost, but also improve the life to save mold cost, more important to produce high quality children’s bath mold to enhance the market competitiveness. Our company according to years of experience in the bath mold, in the processing classification surface design around the exhaust system. This not only the reinforcement is very much, and does not affect the product brightness and defect beauty.

two. Our company in the lighting above are all artificial, 200 #, 800 # lighting, 1500 # polishing are high level.

three. With the development of high technology content, the mold material, quality, variety and performance are updated requirements. Large long-life mold market is more and more favored by customers. In many years of manufacturing experience, our company has summed up the unique processing process, which saves a lot of cost for different molds, and greatly improves the competitiveness of products in the market.